- 425 views

SHIPBUILDING TRADITIONS OF MANDVI

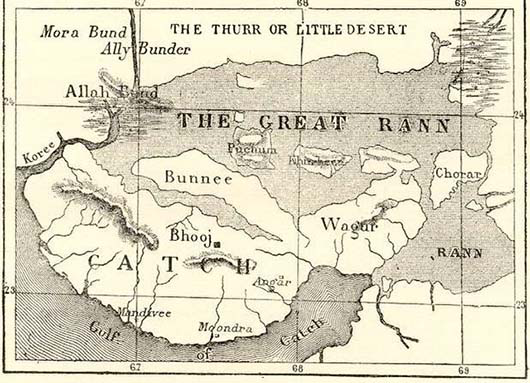

The once-isolated island of Kachchh was bordered by vast treeless tracts of salt marshes called the Rann (desert) on the north and east-end and open to the sea and its bounty on the south and west. L F Rushbrook Williams, in his book, The Black Hills: Kutch in History and Legend, says that it is “no wonder that the Kutchis became a seafaring race”, as the sea has been their main route to and from the rest of the world. This long seafaring tradition was carried on not only by sailors but also by traders and merchants who were frequent visitors to East Africa, Arabia, and the Persian Gulf. So skilled were these Kachchhi seamen that when Vasco da Gama discovered his route from Europe to Asia, he had a Kachchhi sailor called Kanji Malam who helped him navigate through the rough seas. Malam hailed from a small shipbuilding hub called Mandvi.

A map of Kachchh from the 1880s

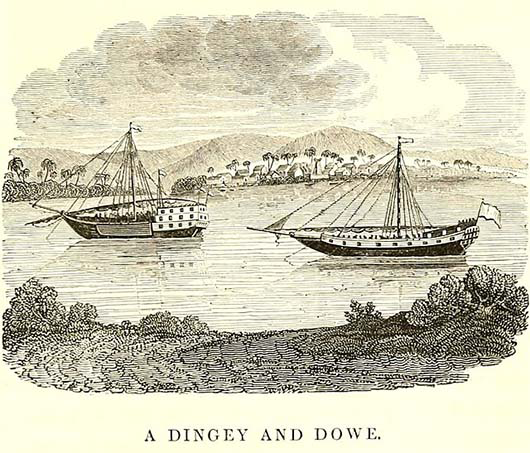

A Dingey and Dowe.

Established in 1581 by the first Jadeja ruler of Kachchh, Rao Khengarji I, Mandvi was a wealthy port town and shipyard located at a crucial junction of the maritime spice trade route and the desert camel caravan route. Its 400-year-old shipbuilding history can be seen even today as one drives by the River Rukmavati on the Bunder Road. The massive, wooden Kachchhi dhows made by the Kharwa community line the bank of the river and are considered the largest handicrafts in the world. The term dhow is a generic term used for a range of traditional sailing vessels with one or more masts or lateen sails (a triangular sail attached to a cross beam and controlled as per the winds). Dhows are speculated to have been invented either by the Indians or the Arabs and were trading vessels that carried goods along the coast of Arab countries, East Africa, and the Indian subcontinent.

Construction of a Kachchhi ship on the banks of River Rukmavati Traditional Shipbuilding Center, Mandavi, Gujarat

These 2000-tonne capacity vessels are made of sal wood imported from Malaysia, Indonesia, and Burma or the wood of the local babool trees. The process of making a dhow starts by laying the pathan: a long beam forming the base of the ship’s hull. The frame to support the boat’s shape is built around it, and large planks of wood called the vakias are chiselled into shape to mount on this base. Once the curves of the ship have taken shape, a layer of wood made of planks called patias is fitted on the outside. These planks are coated with mud and heated over the fire before being gently curved into shape. After they are firmly secured with nuts and bolts, the gaps between the planks are filled-up with a sealant made of cotton dipped in fish oil to make the vessel airtight.

This process of sealing is repeated multiple times to make the ship sturdy enough to weather stormy seas. Today, keeping pace with modern technology, many Dhows use modified boat engines instead of the traditional cloth sails.

Mandvi Shipyard - the beginnings of a ship

Outer layer of wood made of curved patia. "Epic Construction"

Mandvi is also home to the Sagar Ship Model Museum and Workshop, where replicas of various types of traditional Indian and foreign ships are crafted. The workshop was founded by Shivji Buddh, who is now over 90 years old and began sailing at the age of just 7. He explains that Gujarati sailors heading toward Africa would pray to the sea goddess Sikotar Ma for a safe journey. There is even a temple dedicated to Sikotar Ma on Eden Island in Seychelles. To seek the goddess's blessings and protection, sailors would offer a model of the ship they were traveling in to the goddess.

Government of India

Government of India

Recognizing the ongoing need to position itself for the digital future, Indian Culture is an initiative by the Ministry of Culture. A platform that hosts data of cultural relevance from various repositories and institutions all over India.

Recognizing the ongoing need to position itself for the digital future, Indian Culture is an initiative by the Ministry of Culture. A platform that hosts data of cultural relevance from various repositories and institutions all over India.